BioClad® Antimicrobial Products offer Lifetime Armor in the War against Micro-Organisms

Wednesday, 21 September, 2016

BioClad® is the world’s first proven antimicrobial PVC hygienic wall cladding. Antimicrobial silver ion is impregnated into the hygienic cladding panels at the time of manufacture. This helps stop the growth of bacteria and mould which works continuously for the lifetime of the panels, reducing levels of bacteria such as MRSA, E Coli, Legionella, Salmonella and mould (including Aspergillus Niger) by up to 99.99%.

Utilising Antimicrobial Technology, BioClad® products have been Proven to inhibit growth and control bacteria 24/7, not for a few years but guarantee protection for the expected lifetime of the BioClad antimicrobial products.

BioClad® incorporates BioCote® silver ion antimicrobial technology. Silver ion technology is a safe, natural antimicrobial that is added at our point of manufacture ensuring it is present throughout our virgin PVC sheets. This manufacturing process is not, just a surface treatment needing to be revitalised, it is not a mere disinfectant cleaning solution whipped over during the cleaning process, BioClad® Antimicrobial products ensure continued protection guaranteed for its lifetime.

BioClad® has been proven to work in real-world environments.

An independent study was undertaken in a UK Aged Care facility kitchen where 35 surfaces were tested for their bacteria levels. The BioClad hygienic wall cladding registered a 0 level of bacteria.

Date of study: October 2012

Study conducted and report written by Dr Richard Hastings, Microbiologist, Affiliate Microbiology Department, Life Sciences Department, University of Warwick, CV4 7AL. Study and report reviewed and audited by Dr Pamela Simpson, Independent Consultant Microbiologist, Whitewater Technologies Ltd, DY8 2GB.

Study Aim

This study aimed to compare levels of bacterial contamination isolated from surfaces in a busy kitchen situated in a UK Aged Care facility. The study’s main objective was to compare bacterial contamination on the antimicrobial wall cladding with other surfaces in the kitchen. The care home kitchen had been fitted with BioClad® PVC wall cladding (Advanced Hygienic Cladding Ltd, Harrogate, UK) at the time of construction in 2011. All walls in the rectangular-shaped room were fitted with BioClad® from ceiling to floor. The antimicrobial performance of the wall cladding was to be appraised according to the findings of the study.

Methods

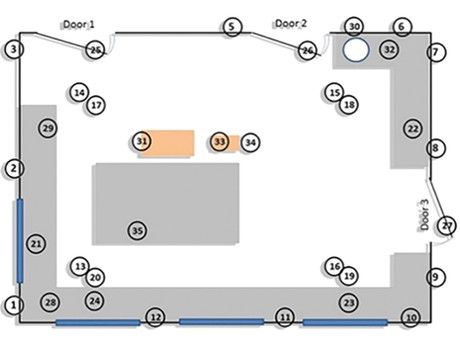

Transport medium swabs were collected from various surfaces situated in a working kitchen (Fig. 1) of a recently commissioned (2011) care home for the elderly located in the UK. Swabbing was performed by rubbing an object’s surface area of 25cm² (typically 5cm by 5cm) with the cotton tip of a pre-moistened bacterial transport swab. Objects swabbed from the kitchen are identified in Figure 1. Swabs were transported to the microbiology laboratory for processing but kept at 4°c during transport. Bacteria collected on the swabs were transferred to two types of solid growth media; plate count agar and brain heart infusion agar containing 5% horse blood. Cultures were incubated in an aerobic environment at 36°c for 48 hours. After incubation, the amount of bacterial growth isolated from each swab was quantified by colony counting and the diversity of growth estimated by inspection of colony types. Isolates presenting a colonial appearance suggestive of a pathogen were Gram stained and presumptively identified.

1: Floor plan of kitchen swabbed in study. Numbers indicate approximate positions of swabbing points and correspond with Swab No listed in Table 1.

Concluding Statement

This study revealed a variety of bacterial counts on different kitchen surfaces. Numbers of bacteria isolated from the surfaces ranged from none (zero) detected to over 1000 colony forming units from 25cm² sampling area. Only two surface types did not produce bacterial growth upon swab culture – BioClad® wall cladding and a suspended plastic ceiling tile. It does not follow that these surfaces were sterile (i.e. totally free from microorganisms), as bacteria may have been present on these surfaces that were not able to grow as colonies on the media used in this study, or the bacteria were present in such low numbers per unit surface area that the sensitivity limit of the isolation techniques used was exceeded. Given the ease of demonstrating the presence of diverse bacteria from all other surfaces examined in the kitchen, it is reasonable to suppose those surfaces that yielded no bacterial growth on culture were not solely contaminated by noncultivable bacteria rather numbers of bacteria on them were very low or, indeed, were absent. Thirteen swabs yielded no bacterial growth. Twelve of the thirteen surfaces swabbed were BioClad® wall cladding. A strong explanation for this observation must be the activity of BioClad’s® antimicrobial feature. Previous laboratory analysis of BioCote® treated BioClad® wall cladding according to the ISO22196:2011 protocol (Measurement of antibacterial activity on plastics and other non-porous surfaces) demonstrated this material to possess a potent antimicrobial property under laboratory conditions. This study suggests BioClad’s® antimicrobial efficacy is transferable to the working environment.

Bioclad’s 2-Hour Benchmark

BioClad panels offer antimicrobial protection. They do not only protect against incidences of bacteria. BioClad offers protection against protozoans, fungi, mould, and a range of other potentially harmful microbes, including bacteria. With BioClad you get a superior second defence barrier for those hygiene-critical areas, and this chart demonstrates just how effective it is. Please don’t just take our word for it. Every batch of BioClad is independently tested, and data from field testing has also been obtained independently. The silver ion technology BioClad uses interrupts the breeding cycle of surface microbes, and leads to their eradication in well-maintained critical areas such as operating theatres, kitchens, shower rooms etc. that would otherwise provide excellent breeding conditions for micro-organisms. Typical results for BioClad tested to ISO 22196:2007 standards are a reduction in overall bacteria load of over 99%. Environmental tests ensure BioCote technology performs equally in real life as in a lab. The graph shows that even after only 15 minutes the reduction in living bacteria is over 50% and after 2 hours over 99%.

Results Table 1:

Comparison of abundance and diversity of bacteria isolated from surfaces in a working kitchen located in a UK care home.

For more information contact Bryan Burrows, General Manager of BioClad Australia on 0422 819 605 or email sales@bioclad.com.au or visit www.bioclad.com

![]()

National Allied Health Workforce Strategy: a lasting reprieve?

Hospital + Healthcare speaks with Chief Allied Health Officer Anita Hobson-Powell,...

ADHA accelerates connected care for allied health

After attracting substantial interest from software vendors, the Australian Digital Health Agency...

South Australia gains its first fully rural medical degree

Designed to address the critical shortage of doctors in regional, rural and remote areas,...